CO2 Dissolved: carbon dioxide storage and capture

Transcription

CO2-Dissolved is an innovative CO2 capture and storage concept developed by BRGM and its partners since 2012. Particularly well adapted to industries with low CO2 emissions, CO2-Dissolved offers a solution to eliminate or significantly reduce their carbon footprint.

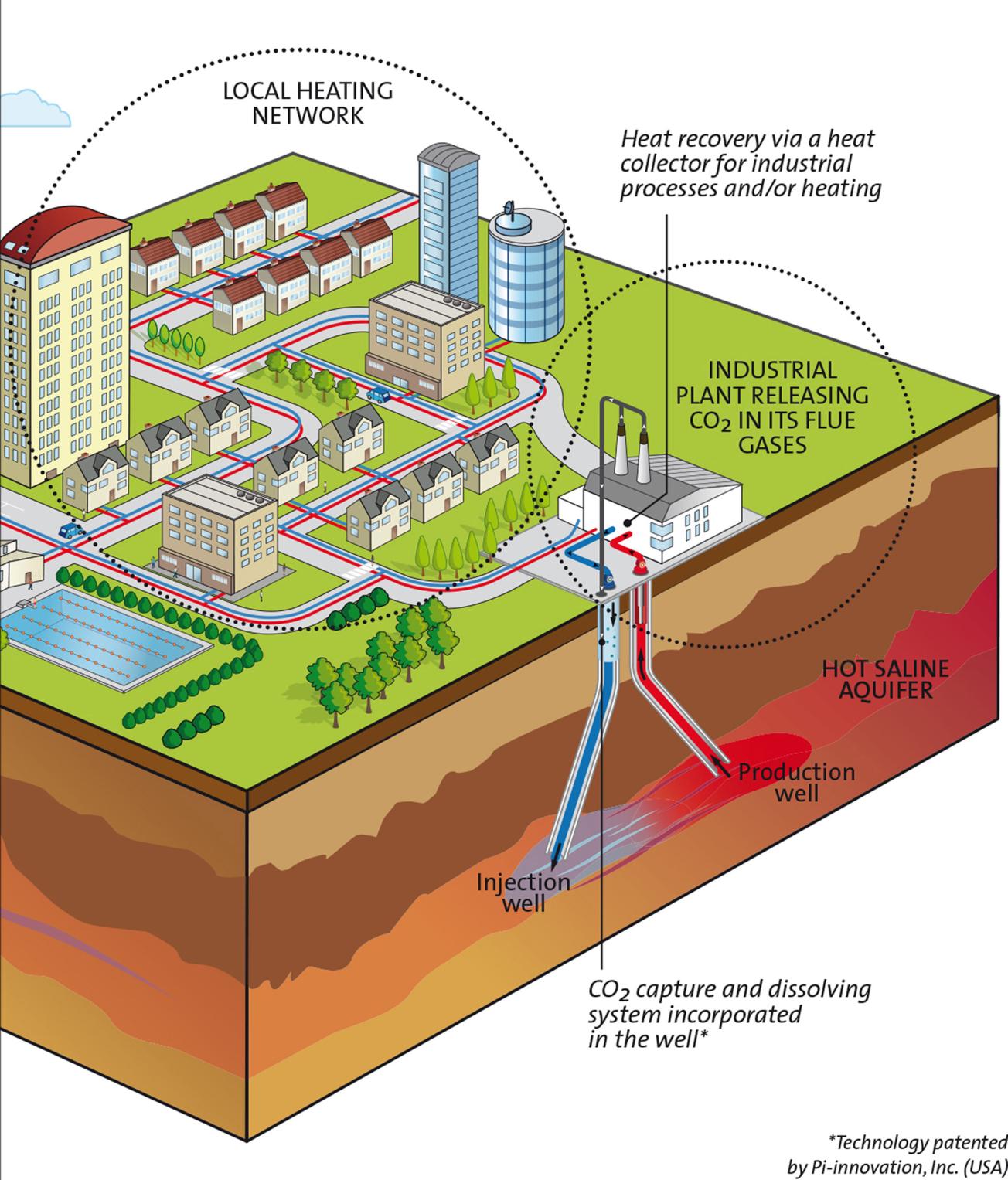

The technology consists in storing CO2 fully dissolved in the water of an aquifer deep down in the subsurface. This water is far too salty to be used as drinking water, and it has the advantage of being naturally hot with temperatures between 40 and 90° C.

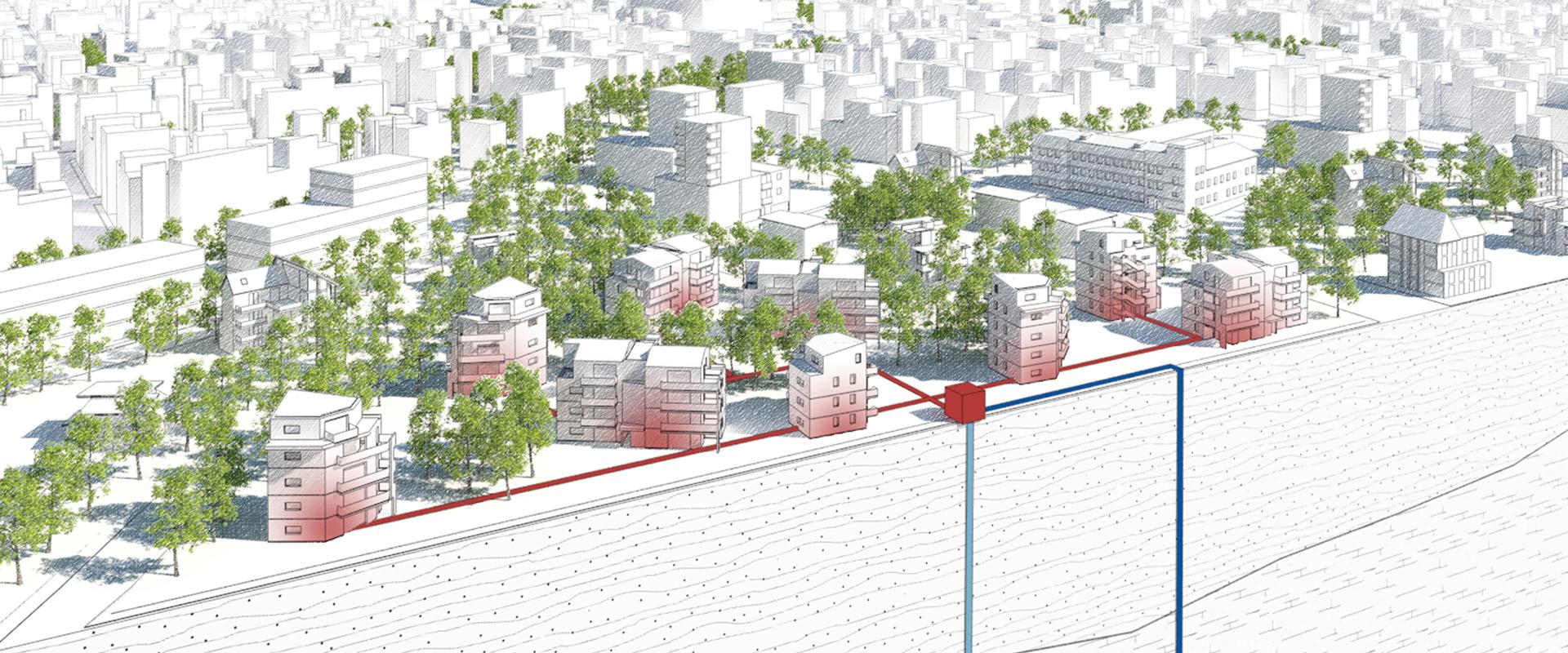

The hot water is first pumped up through a well from the aquifer to the surface in order to recover the energy, which can be used for example to supply a heating network for homes. Once the calories have been removed, the cooled water is then used to dissolve the CO2 previously captured from the factory fumes. The cold water and dissolved CO2 are then reinjected into the same aquifer via a second well.

This pumping / reinjection cycle using a set of two wells (called a doublet) operates continuously, as in any classic deep geothermal installation, a technique widely used in the Ile-de-France Region in the Paris Basin. The difference here, is the addition of CO2 in dissolved form in the reinjected water, with a maximum concentration of around 50 kg of CO2 per cubic meter of water.

Calculations show that it would be possible to store in this manner up to 80 to 150,000 tons of CO2 per year, per site. In France, more than 400 industrial sites emitting low quantities of CO2 have been identified that also have underground geothermal resources. This combination enables the potential implementation of CO2-Dissolved. Should CO2-Dissolved be deployed at all compatible sites, this would remove the equivalent of the annual CO2 emissions of 12 million cars.

CO2-Dissolved therefore offers a win-win environmental and economic benefit by reducing industrial CO2 emissions, while producing clean and renewable energy.

This technology brings an innovative solution to small industrial emitters scattered across the territory, allowing them to reduce their carbon footprint and thus contributing to the major challenge of climate-change mitigation.

While there is no doubt that geological storage of CO2 is necessary to cut atmospheric greenhouse gas emissions, the implementation,safety and monitoring conditions required raise scientific, technical, economic and social issues that are slowing its development in the short term. Storing CO2 on a small scale close to the emission sources would be an additional and possibly alternative solution. The 3-year ANR CO2Dissolved project explored this possibility. With 7 partners* co-ordinated by the BRGM, the project demonstrated the feasibility of combining the storage of dissolved CO2 in an aquifer with the extraction of geothermal heat.

This solution has several advantages. The idea is to store the CO2 produced by an industrial facility on the same site by injecting it in dissolved form into an underlying deep saline aquifer. The water is pumped up and subsequently reinjected with the dissolved CO2 through one "injection" and one "production" well, similar to the geothermal doublets used to supply heating networks. In situ CO2 storage would reduce both the costs and risks of transporting the gas, which, in addition to heat recovery, makes this an attractive solution, subject to the existence of suitable aquifers in the right location and proper control of the process.

Storage of industrial CO2 emissions coupled with heat production

Feasibility and risk control

Because CO2 is only is soluble in brine within certain limits, and because of the standard flow rates in geothermal doublets (250-350 m3/h in the Paris Basin), this is a relevant solution for small-scale industrial emissions of CO2 (< 150 000 t/year). The storage sites targeted are deep aquifers (1 500 - 2 500 m) with temperatures in the region of 60 to 80°C. In France, 650 potentially compatible industrial sites (accounting for 25% of emissions in France) have been identified.

The American partners of the project have developed an innovative CO2 capturing process in which water is the only solvent. Possibilities for integrating this process into the CO2Dissolved system have been investigated, and depend on CO2 concentrations in flue gases and the possible need for separation prior to injection. Unlike large-scale storage, where the CO2 is injected in supercritical form, in this case it is entirely dissolved in the brine of the aquifer. This removes the risks of a gas bubble forming underground, which could rise to the surface.

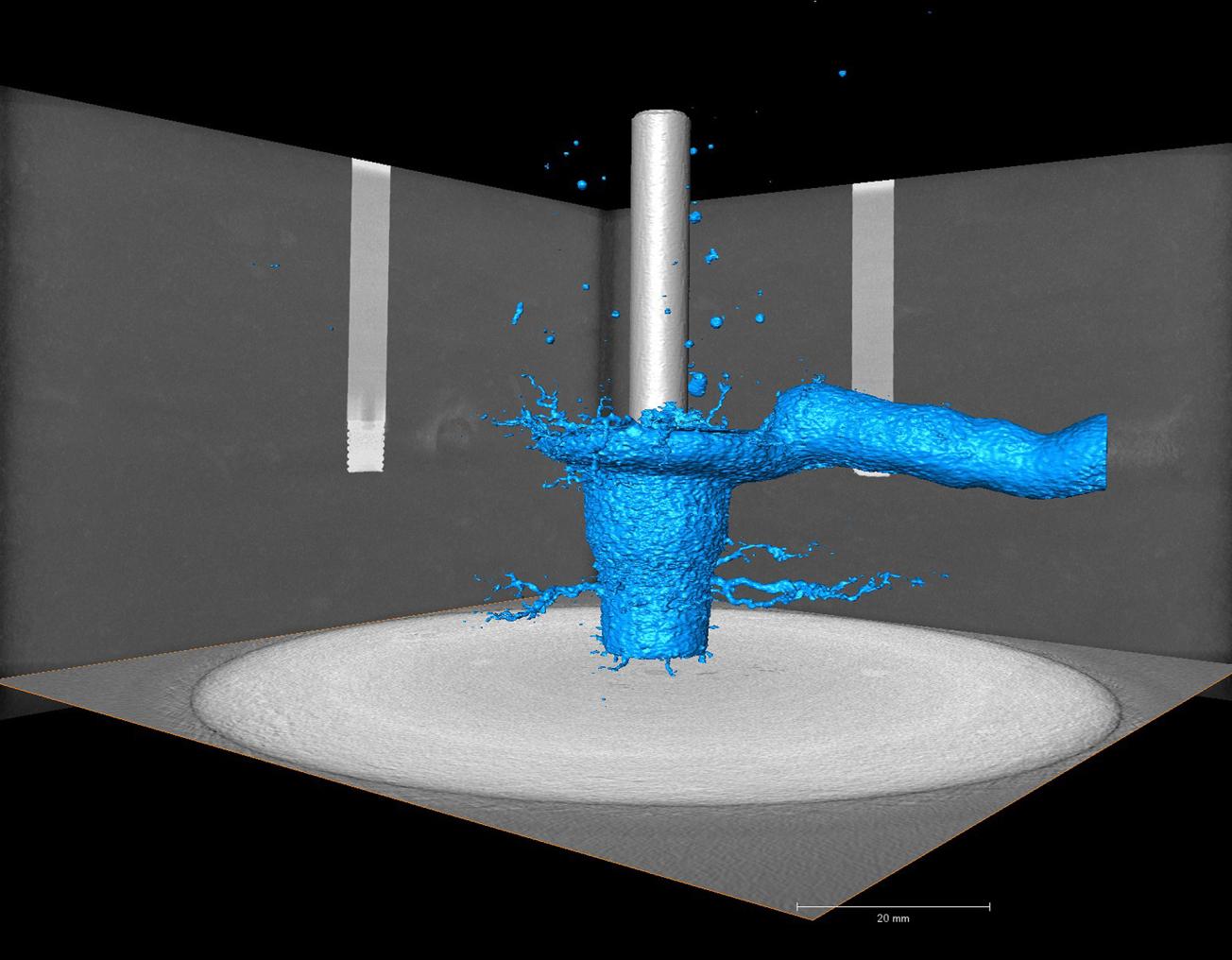

The impacts on the rock of injecting acid water and the resulting chemical reactions that depend on the hydrogeological characteristics of the environment have been digitally simulated and repeatedly tested at an experimental facility. The economic impact has also been investigated, in the case of a sugar mill and distillery in central France, and has demonstrated the viability of most of the scenarios simulated, thanks to the economic benefits of the heat recovered.

The next stage will be to implement a demonstration pilot on an industrial site. The first steps are already under way with the new "Pilot CO2-Dissolved" project financed by the Géodénergies scientific interest group.